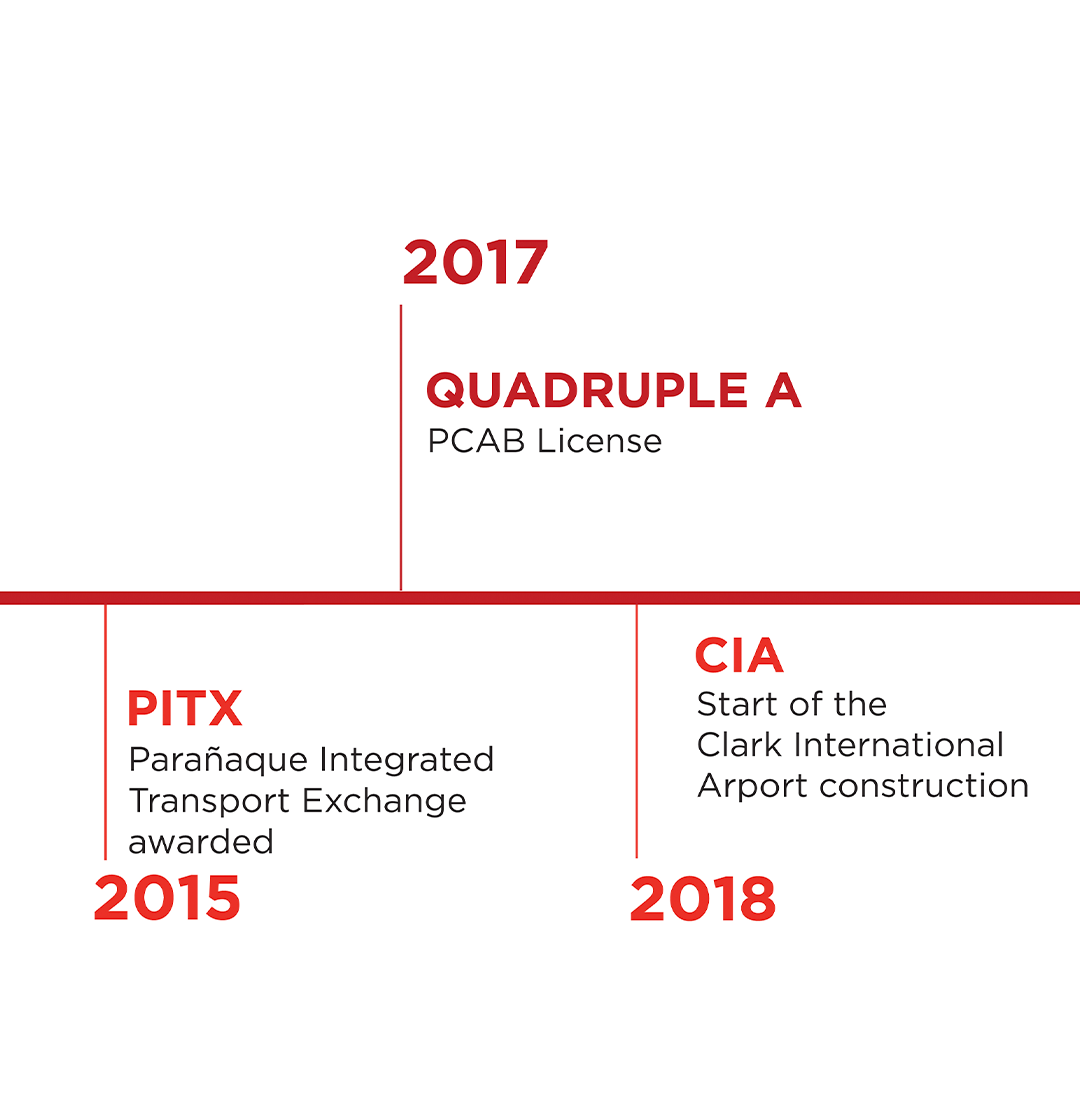

About Us

At Precast and Construction Solutions by Megawide, we are proud to offer top-quality precast construction solutions from a trusted leader in the construction industry. With a commitment to excellence and innovation, our Precast unit delivers cutting-edge precast products that revolutionize the way buildings and infrastructure are constructed.

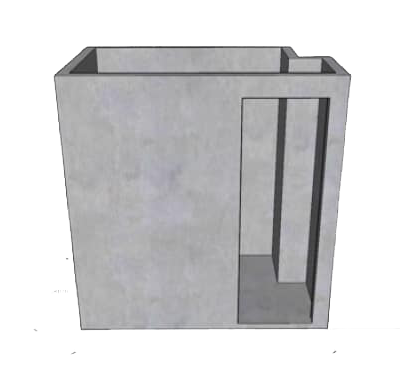

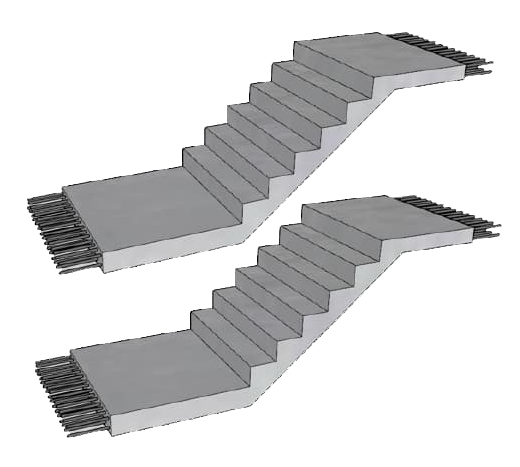

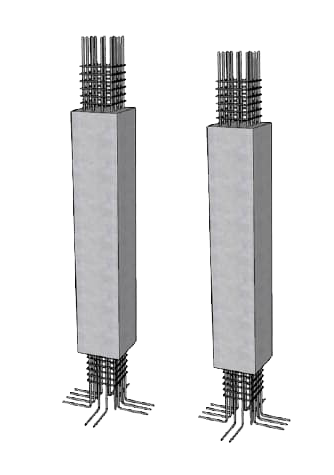

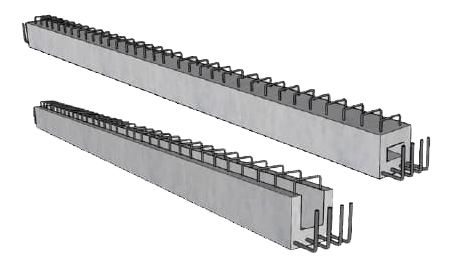

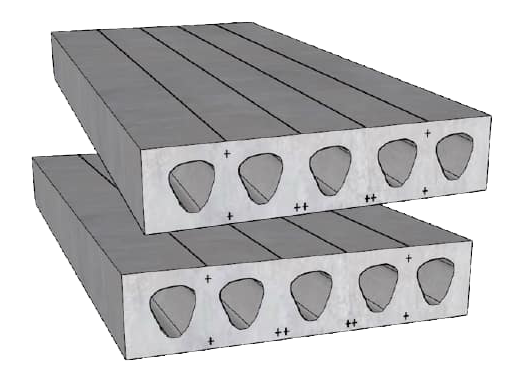

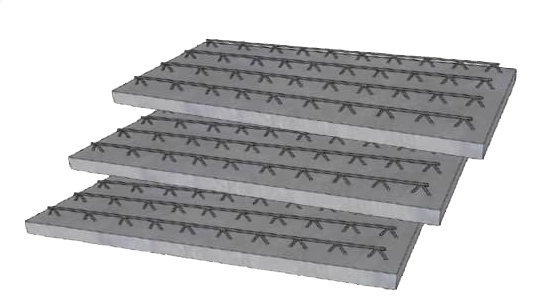

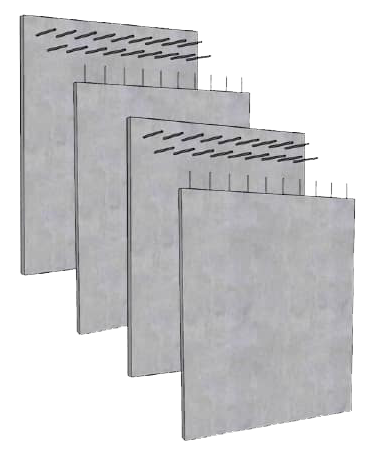

Our Precast products encompass a wide range of prefabricated components, including beams, columns, slabs, walls, and specialized elements tailored to meet the unique requirements of each project. These precast elements are manufactured with precision and efficiency at Megawide’s state-of-the-art facility in Taytay, Rizal, utilizing advanced technology and stringent quality control measures to ensure superior performance and durability.

By the Numbers

Key features

Our precast products are designed to meet the highest standards of quality, functionality, and aesthetics. With a focus on innovation and sustainability, we offer customizable solutions that enhance the architectural and structural integrity of buildings and infrastructure.

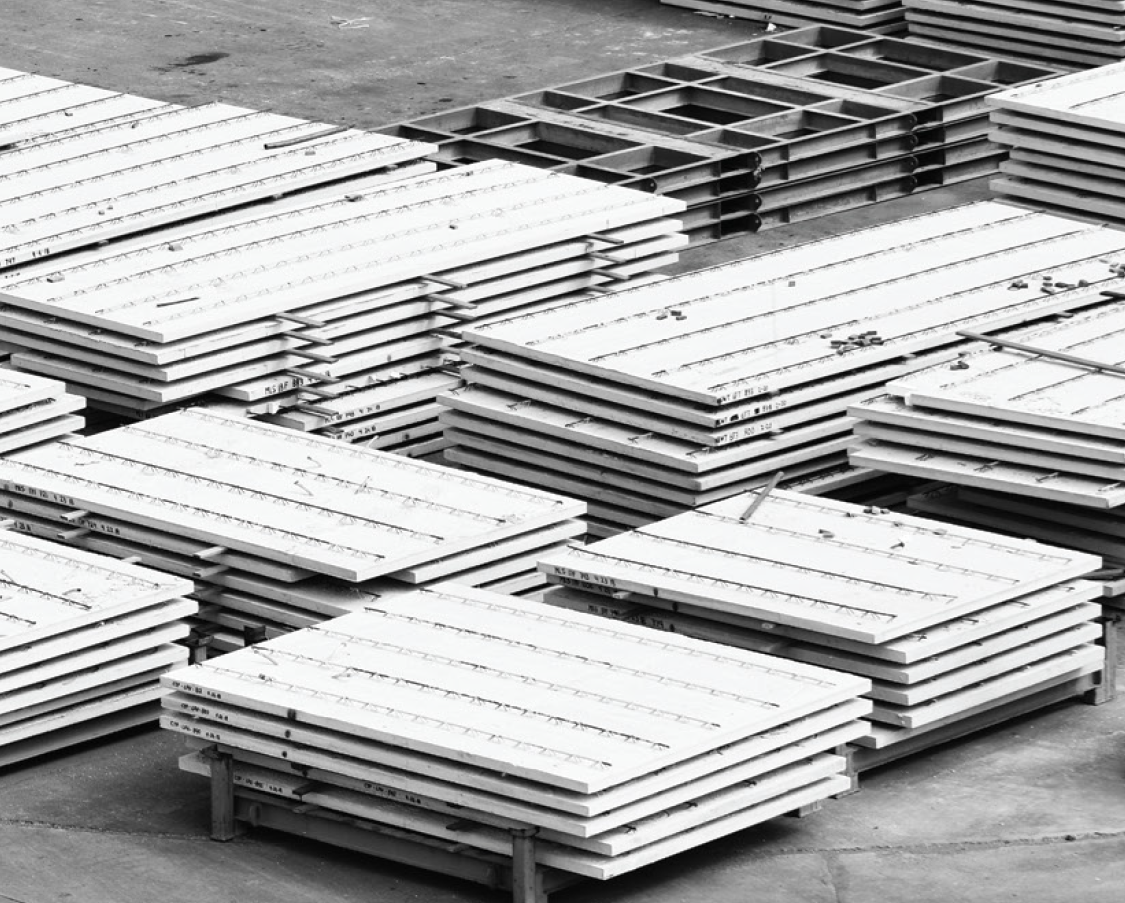

Our Precast business unit utilizes advanced manufacturing processes and equipment to produce high-quality precast elements with exceptional precision and consistency. Our automated production facilities ensure efficiency, accuracy, and adherence to project timelines.

Quality is paramount in everything we do. From raw material selection to final inspection, our Precast products undergo rigorous quality assurance procedures to meet and exceed industry standards. Our commitment to quality ensures the long-term performance and reliability of our precast products.

Prefabricated precast elements offer significant time and cost savings compared to traditional construction methods. By manufacturing components off-site and delivering them ready for installation, we streamline the construction process, reduce labor requirements, and minimize on-site disruptions.

Whether it's residential, commercial, industrial, or infrastructure projects, Precast offers versatility and customization to suit diverse construction needs. Our experienced team works closely with clients to develop tailored solutions that meet project specifications and requirements.

We are committed to sustainable construction practices that minimize environmental impact and promote resource efficiency. Our precast products are manufactured using eco-friendly materials and processes, contributing to green building initiatives and LEED certification requirements.

We prioritize collaboration and partnership with our clients, architects, engineers, and contractors. We believe in fostering strong relationships built on trust, communication, and mutual respect to deliver successful outcomes and exceed client expectations.

Comparison

Precast

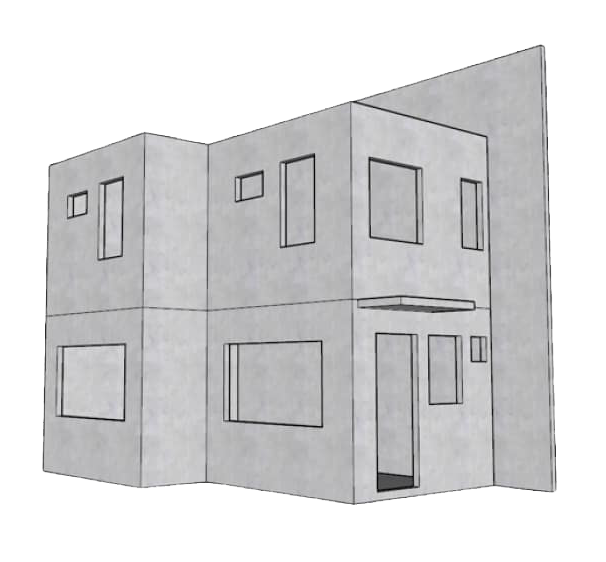

A construction product produced by casting concrete in a reusable mold or “form” which is then cured in a controlled environment, transported to the construction site and lifted into place.

- Faster construction process

- Lower long-term cost

- Waste Savings

VS

Cast in place

Also known as poured-in-place, is a concreting technique which is

undertaken in situ or in the concrete component’s finished position.

- Prone to project delays

- High labor requirements

- Uncontrolled subject

Services

Design and Customization

The design and engineering team creates a blueprint best fit for client design requirements. Client preference on precast percentage is followed, but the team gives suggestions to ensure an efficient construction process.

Precast Production

Precast concrete is produced at the Megawide Precast Plant in Taytay, Rizal. Experts oversee the factory-controlled production, which eliminates the interference of unfavorable conditions and other external variables in the production. Before release, every precast product is inspected and tested to ensure high concrete quality

Delivery and Installation

Precast products are assembled in the factory and transported to project sites using Megawide trucks. The

precast construction installation team of experts and seasoned workers guarantees the safety and accuracy

of the installation process with strict attention to detail.

Products

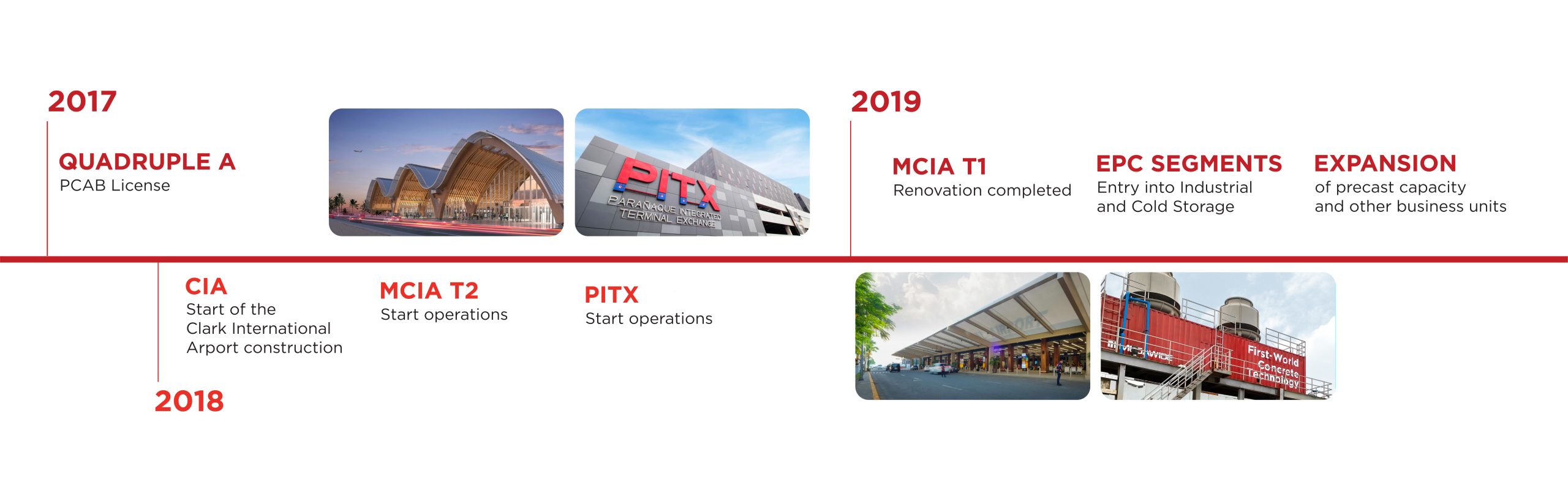

Projects

Skyway Stage 3

Client Name:

-

Scope:

Precast Half Slab

Mactan-Cebu International Airport

Client Name:

-

Scope:

Carbon Market

Client Name:

Cebu2World Development Inc.

Scope:

Paranaque Integrated Terminal Exchange (PITX)

Client Name:

MWM Terminals, Inc.

Scope:

Precast wall

Project 1

Project 2

Project 2

Project 2

Make your ideas happen

Achieve your construction vision with our customized precast solutions. Tailor-made for your project needs, our top-quality products effortlessly turn your ideas into reality!

Clients